Failure to install the copper combustion seal or an improperly torqued injector can result in injector failure and potential engine damage. The copper combustion seal is included with our remanufactured injectors

Injector failure as a result of these conditions is NOT covered by Pensacola Fuel Injection’s Warranty Policy.

Follow these steps to ensure your LB7 Fuel Injectors are correctly installed.

- Ensure the copper combustion seal is present on the injector being replaced. If the seal is missing inspect the injector bore for seal and remove prior to installing replacement injector.

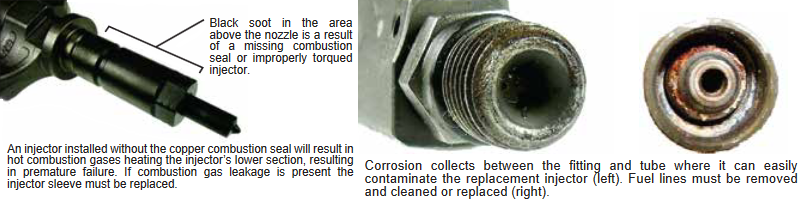

- If the injector being replaced shows signs of combustion seal leakage (Figure 4) and the prior injector is missing the copper seal it will be necessary to replace the injector sleeve prior to installing the replacement injector. Failure to do so will result in leakage of the new combustion seal and injector failure. To clean light carbon build-up from injector bore use GM special tool EN-47909 and refer to GM TSB 05-06-04-067.

- Always inspect the injector bore for corrosion, damage or leakage prior to installing new injector.

- Ensure each injector is torqued to manufacturer’s specification.

– Fuel Injector Hold Down Bolts: 37 lb-ft (50Nm)

– Fuel Injector fuel pipe nut (The nut on the hard fuel line going to the injector): 30 lb-ft (41 Nm)

– Fuel Injector Return Line Banjo Bolts: 106 inch-lbs (12 Nm)

Additional LB7 Fuel Injector Tech Tips:

- Always replace the Fuel Filter when replacing the Fuel Injectors.

- If you are diagnosing injector driver diagnostic trouble codes P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208 or cylinder bank shut down codes P2146 or P2149, the cause may be related to a damaged Fuel Injection Control Module (FICM) wiring harness. The harness may come in contact with the alternator, alternator bracket or FICM harness retaining bracket. This can damage the harness resulting in diagnostic trouble codes, cylinder misfire or cylinder bank shut down. This condition could be mis-diagnosed as an injector failure. For more information and repair information consult GM TSB 09-06-04-034.

- When replacing the fuel injectors, all fuel lines should be completely removed, inspected and cleaned or replaced.

- The number one cause of premature LB7 injector failure after replacement is contamination transfer between the fuel line and injector. This is the subject of GM TSB 03-06-04-036B. The design of the LB7 fuel lines that connect the high pressure rail to the injector are extremely susceptible to corrosion on the inside of the fitting that passes through the valve cover. Because it is exposed to under-hood elements, the area between the tube and fitting can collect water and debris. Water corrodes the area between the tube and fitting and when removed the corrosion and debris is broken loose, which will enter the fuel supply inlet of the new injector. Because the fuel line is down stream from the fuel filter on the high pressure side, the contamination enters the injector and can cause premature failure of the new injector. Injector failure due to contamination is NOT covered by Pensacola Fuel Injection’s Warranty Policy.